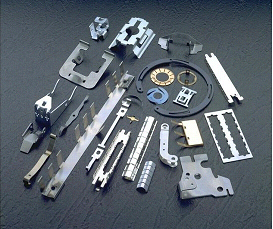

Product

TRANCIATE

Filo da: 0,20mm a 10mm

Macchine utilizzate: (fino a 160 Ton.) Manzoni, Zani, Gaiani, Dellavia, Sangiacomo

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Crest-to-Crest Wave Springs with squared-shim ends provide a 360° contact surface when compared to the wave point contact of plain ends. The shim-ends under load, more evenly distribute the springs force upon adjacent components. This feature is similar to the concept of double-disc grinding springs for a flat surface. Shim ends have also been used to affix springs to mating components, as a flat locating surface that may be attached by various methods in the assembly.

-

Crest-to-Crest Wave Springs are prestacked in series, decreasing the spring rate proportionally to the number of turns.

-

Our spring range produced from wire and strip has a unique breadth and is known for its durability, adaptability and variation ability. Our springs are used in just about every industry sector, which could be power generation, paper and pulp industry, but also offshore, automation and infrastructure. CLOCK SPRINGS Clock Springs – also called hair springs – is a torsion spring that is optimum for installation spaces that are limited axially, but with more space radially. They are made from strip material or flat rolled wire that is wound in a flat, spiral shape. The coils generally form a linear spiral and have the same coil distance everywhere in the unloaded state. They have many similarities with power springs, but have an operating range that is rarely more than one turn. The Lesjöfors production range includes clock springs primarily of high-tensile spring steel or stainless steel grades, but also in soft material that is hardened and tempered after forming. COMPRESSION SPRINGS Compression Springs is the most common type of springs. The majority of compression springs are cylindrical and linear, but to this group belongs also conical, barrel shaped, tapered out ends and more. The design can be adjusted to fulfil a wide range of requirements concerning spring characteristic. We provide both stock springs and bespoke springs. Material grades covers the whole range from normal spring steel to nickel alloys, titanium alloys and copper alloys. We cold coil springs up to wire diameter around 18 mm and hot coil for larger springs. Our maximum bar diameter for hot coiling is 65 mm. The conditioning processes – heat treatment, shot peening and presetting – are adapted according to the requirements. We offer different surface treatments for corrosion resistance or desired visual appearance. CONSTANT FORCE SPRINGS Constant Force Springs are manufactured from flat strip material and spooled to a specific curvature matching the needed pull force. There is practically no limit on extension speed and acceleration. The springs can be fitted in a number of ways and extended partly or completely. Applications for constant force springs include window balancers, counter balances, and point-of-purchase shelving and displays. DISC SPRINGS Disc springs (also called Belleville springs) are geometrically a cylindrical washer with a slightly conical shape. It is used as compression spring and is the best solution when forces are high and travel relatively limited. Disc springs can be stacked in series or in parallel, which increases travel and/or force. Disc springs have applications in many sectors. We manufacture them in spring steel, stainless steel or super alloys depending on the requirements. GARTER SPRINGS A Garter Spring is a circular ring made from a coiled helical spring bent into a circle and with the two ends connected to each other. A garter spring will create a radial force directed towards its center when the radius of the garter spring increases. Garter springs are often used to ensure conduction in electrical connectors but also in other applications where a radial force between two circular components is desired. POWER SPRINGS Power Springs are made of strip material and typically installed between an inner shaft and an external housing. A torque is generated between the inner shaft and the external housing. The number of turns is individually determined and can be as much as 50. Different coiling techniques exist to give the material the desired curvature that matches the torque-rotation requirements. Power springs have many similarities with clock springs, but have a much larger operating range in terms of number of turns. Power springs can be used for winding cables, hoses, safety belts and much more. SNAP RINGS A snap or retaining ring is a fastener or retaining ring that consists of a semi-flexible metal ring with open ends that can be snapped into place. It fits in a groove on a shaft or inside a bore and locates the shaft axially in one direction. Snap rings are used in applications such as assemblies on shaft, gear systems and automotive engineering. Lesjöfors manufacture snap rings to individual customer specifications. We use different materials with individual follow-up work processes such as deburring or surface coating. SPRING TINES In the agricultural industry, spring tines are used for machinery and equipment for grassland harvesting and tillage. They broadly belong to the product group of torsion/leg springs Depending on the application, a distinction is made between rake tines, pick-up tines and tedder tines, which differ essentially in their geometric shape. Our spring tines are made of high-quality spring steel and are exclusively cold-formed, meeting the highest quality requirements. To achieve premium quality, special heat treatment and surface coating processes are carried out during production. TENSION SPRINGS Tension springs are designed to give a specific pull force when extended to a a specific length. Our tension springs have a material dimensional range from 0.03 – 26 millimeter. Cold coiled extension springs can be given an initial tension which needs to be overcome before any elongation of the spring takes place. The level of initial tension can be controlled. Most common ends are different types of end loops and hooks, there are also a wide range of other mechanical attachment possibilities such as coiled in and screwed in attachments. Examples are, half hooks, German loops, English loops, extended hooks, side hooks, side loops, screw plugs and screw shackles. TORSION BAR SPRINGS Torsion Bar Springs is a good alternative to clock springs or helical torsion springs, when a rotational torque is needed in applications where the spring shall fit into a space that is limited radially, but with lots of space axially. The active part of a torsion bar is a straight wire with circular cross section. The ends are designed to allow for the torque to be introduced. TORSION SPRINGS Torsion Springs – or helical torsion springs – is the most common spring type when torque is desired together with a rotating movement. The active part is a helical coil of spring wire and the ends (legs) are designed to allow for the introduction of the torque and fit with the abutments of the application. Many applications require two similar torsion springs, but with one right-hand coiled and one left-hand coiled. In some cases, these two springs can be combined into a double torsion spring, which has one right and one left-hand coiled spring body connected to each other. Material grades are the same as for compression springs, covering the whole range from normal spring steel to nickel alloys, titanium alloys and copper alloys. We cold coil torsion springs up to wire diameter 18 mm and hot coil for thicker material. Material with a square cross section is sometimes required to cope with the requirements. VOLUTE SPRINGS Volute Springs are used as compression springs and made from flat material coiled to a volute. The coils of the material overlap each other and are guided radially by each other during compression, thus giving volute spring a stability against buckling that cannot be achieved with conventional compression springs. By using volute springs it’s possible to achieve shorter installation lengths than for compression springs. It all depends on forces and dimensions. Volute springs are typically found in secateurs for gardening and in railway buffers. WAVE SPRINGS Multi-coil Wave Springs are made from flat-rolled spring wire that is coiled to a helical shape and the coils are at the same time given a sinus shaped wave form. The force-deflection relation is created by flattening out the wave form when the spring is compressed. The function is hence like a helically shaped leaf spring. A wave spring suits perfectly in applications where a small installed length is required. For small strokes, the length of a multi-coil wave springs is lower than for conventional helical compression springs. For some requirements, this can reduce installed length by up to 50%. We have a standard stock of wave springs that satisfy the majority of requirements. However, if you need a customized spring with specific dimensions, material etc. we are ready to assist you in designing the most optimal spring solution. WIRE FORMS Wire Forms can have a shape that is limited almost only by fantasy. Many of our wire forms have some kind of spring functionality, for example some quick fastening applications. In most wire forms, the material is stressed in bending and they can be looked upon as leaf springs made from wire. Wire forms are manufactured in wire forming machines or manual for smaller volumes. Our range of material grades basically covers everything available as wire.

-