Service

Machining of metals

Price of the Service

Category of the Service

Company website

3

products -

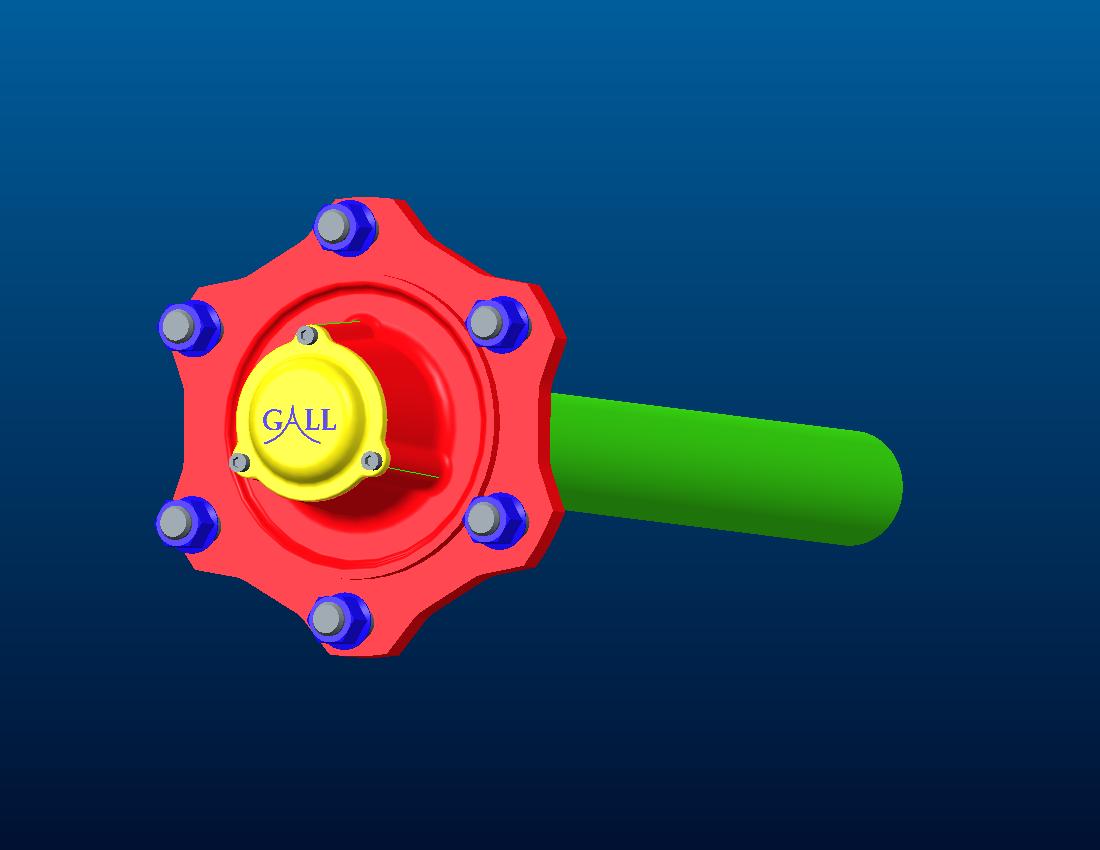

GALL s.r.o.

Our recommended products and services

-

-

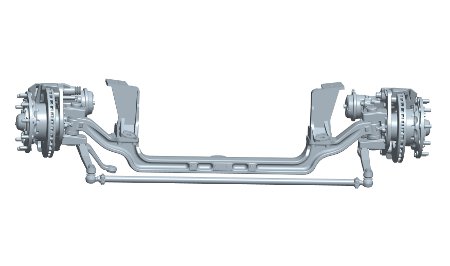

Machining of steel parts

-

Precision Copper Machining – Electrical Conductivity, Dimensional Accuracy & Superior Finish At EROSIÓN DE PRECISIÓN EROPREC, S.L. (ERO-PREC), we offer specialized copper machining services for industries requiring outstanding electrical and thermal conductivity, tight tolerances, and clean finishes. With over 30 years of experience, our team combines cutting-edge CNC and EDM technology to deliver copper components of the highest quality. Why Does Copper Require Specialized Machining? Copper is a soft, ductile, and highly conductive material, widely used in electrical and thermal applications. However, its excellent malleability also makes it challenging to machine. Copper tends to deform under pressure, stick to cutting tools, and produce burrs, which can compromise both dimensional accuracy and surface integrity. At EROPREC, we understand these challenges and apply optimized strategies and tooling to ensure precision machining of copper parts. Benefits of Machining Copper with EROPREC Burr-free and deformation-free machining: Our cutting parameters and tool selection are tailored for soft non-ferrous metals like copper. Tight tolerance control: We consistently achieve micrometric tolerances on complex geometries. Superior surface quality: Smooth, clean finishes ideal for electrical and heat transfer performance. EDM machining for copper: Wire and die-sinking EDM allow precise cuts with minimal thermal impact. Flexible production: We handle prototypes, small batches, and custom production runs. Types of Copper Parts We Manufacture Precision electrical connectors and terminals Transformer and switchgear components Copper EDM electrodes and contact points Heat sinks and thermal interface parts Structural copper parts for power electronics

-

Graphite Machining – Precision & Clean Manufacturing for Technical Applications At EROSIÓN DE PRECISIÓN EROPREC, S.L. (ERO-PREC), we offer high-precision graphite machining services for industries that demand accuracy, cleanliness, and high-performance materials. Graphite is an ideal material for applications requiring electrical conductivity, thermal resistance, and dimensional stability — such as EDM, foundry molds, aerospace, metallurgy, and electronics. Thanks to our specialized CNC equipment and decades of expertise, we produce complex graphite parts with tight tolerances and superior finish, whether for individual prototypes or small production batches. Why Graphite? Graphite is lightweight, electrically and thermally conductive, and stable at high temperatures. Its machinability and resistance to wear make it ideal for both industrial and high-tech applications. At EROPREC, we work with a wide range of technical graphite grades to meet your exact functional and dimensional requirements. Benefits of Graphite Machining with EROPREC High dimensional precision on fragile or intricate components Clean dry machining with dust containment and controlled environments Tailored parts produced to drawing or 3D model CNC machining of all industrial graphite types: isostatic, extruded, molded, impregnated In-house expertise in EDM graphite electrode design and manufacturing Common Applications Graphite electrodes for sinker EDM Non-ferrous casting molds (aluminum, copper, brass) High-temperature thermal components Brushes, electrical contacts, furnace parts Insulating rings, nozzles, guides, and custom parts Graphite Grades We Machine Isostatic graphite (high-density, fine-grain – ideal for precision EDM) Molded and extruded graphite (durable and cost-efficient) Synthetic graphite (low porosity, high purity) Impregnated graphite (for chemically or thermally demanding applications)

-