Product

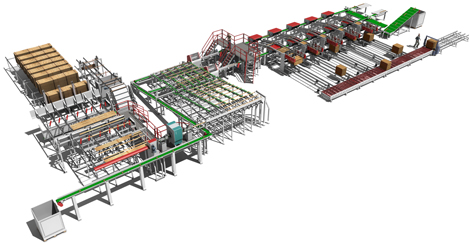

Opti-Solutions

System TM’s lines are characterized by:

- System TM’s optimizing software - the only software available optimizing on both wood resources and the overall line capacity.

- System TM’s individual design. The lines are individually designed and manufactured, always considering the customer’s production and main machines. This ensures our customers high-performance materials handling, and 100% workpiece control throughout the line.

- Complete hard- and software integration between all functions of the line.

- The best return on investment.

- Low labor costs and optimal utilization of the wood, ensure our customers to stay competitive in the global market.

- Higher efficiency for all main machines.

- Automatic production changeover from one central computer.

Price of the Product

Technical Details

Category of the Product

Company website

4

products -

System TM A/S

Our recommended products and services

-

-

![Automation Automation]()

Services and processes We Supply the complete solution for your Automation task Expert advice due to many years of experience taken from projects in different industries. Hardware and software engineering based on specifications unique to each Project. Switchgear implementation by one of our carefully selected partners and technical approval by our specialists. Detailed testing of PLC and control system software is carried out in cooperation with the client in the simulated test environment at Autexis Control. This factory acceptance test (FAT) guarantees smooth and fast on-site implementation and on-time delivery to the Client. Cross-functional project management ensures that the agreed services, deadlines and costs are met. Extensive documentation as well as service and support provided over the entire plant life cycle. Even 24/7, 365 days a year if so desired.

-

Connecting different plant levels to the ERP is a central requirement for the smart factory. The standardised communication modules lay the foundations for using the following modules to generate ‘smart data’ for optimal production monitoring and control. The current system status, the most important production figures and urgent alarm messages are displayed across processes and updated in real time in all plants/systems, thereby ensuring that you can always keep an eye on the entire production process. In tables and/or graphs with clearly organised charts. Production and energy data is used to calculate the relevant key figures and display them in any form. Key figures such as efficiency (OEE), downtimes, runtime factors, availability, order data and energy values can be visualised in the desired graph (waterfall diagram, step diagram, bar chart). The order overview displays the order plan data, including details of bills of materials and routing operations. Production orders can be managed and subsequently approved. All manually and automatically posted order confirmations are also displayed. The products can be automatically labelled using a label printing solution. Thanks to real-time monitoring of the entire production process and the display in the clear traffic light system, it is also possible to detect and correct plant malfunctions across processes at an early stage. Downtimes are reduced to a minimum in connection with KPI/OEE and the maintenance module. If the system to be connected does not have a suitable communication system, production data, such as downtimes, yields, defects/rejects, machine and labour times, can also be entered manually. Quality assurance documents and processes can also be displayed and worked on in the same display (touch panel). All data is saved in MES. Due to a secure and standardised mobile connection, all modules can also be displayed and operated on the smartphone, so that you can always keep an eye on entire production from anywhere and react promptly to major events. Instead of installing the service on site, you can also obtain Autexis IT MES solutions as a cloud service. The securely stored data is continuously evaluated and the responsible persons are proactively informed in the event of any impending disruptions. As a result, not only the information about the life cycle

-

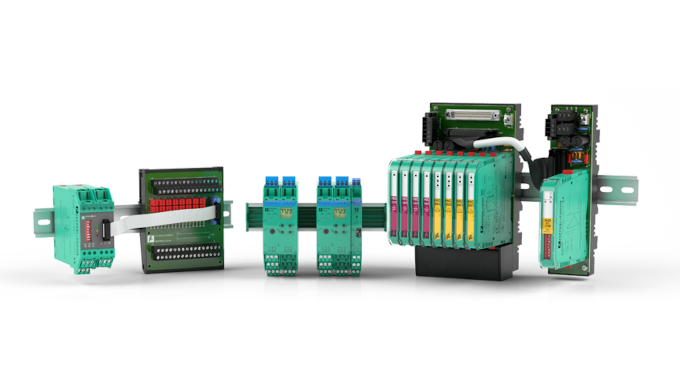

HART Interface Solutions from Pepperl+Fuchs consist of two HART Multiplexer Systems for multiple signal loops and a HART Loop Converter for single loop applications. The Multiplexer is used to connect HART field devices to Asset Management Systems like AMS™ Suite: Intelligent Device Manager from Emerson Process Management. At the heart of HART Interface Solution (HIS), the HART Multiplexer acts like a gateway device, routing communications between the maintenance workstation PC and the HART field devices. It interrogates each HART device, retrieves device information, and stores it in an internal database. This information is made available by the AMS Device Manager or PACTware. The HART Multiplexer also acts as a message coordinator for communication between the maintenance workstation PC and the HART devices. For a single loop solution, the HART Loop Converter allows access to all process variables provided by a field device and transfers them to conventional 4...20 mA loop. This enables it to make use of the hidden measurements done by many field devices and feed them to conventional DCS Systems.

-